Medical Device Contract Assembly

ISO 13485 QUALITY CERTIFICATION

You can also rest easy that as an ISO 13485 certified company, we adhere to the highest quality standards and are committed to maintaining that standard every day. As a result, you don’t have to worry about developing production processes on your own to meet that standard, we have already done it for you.

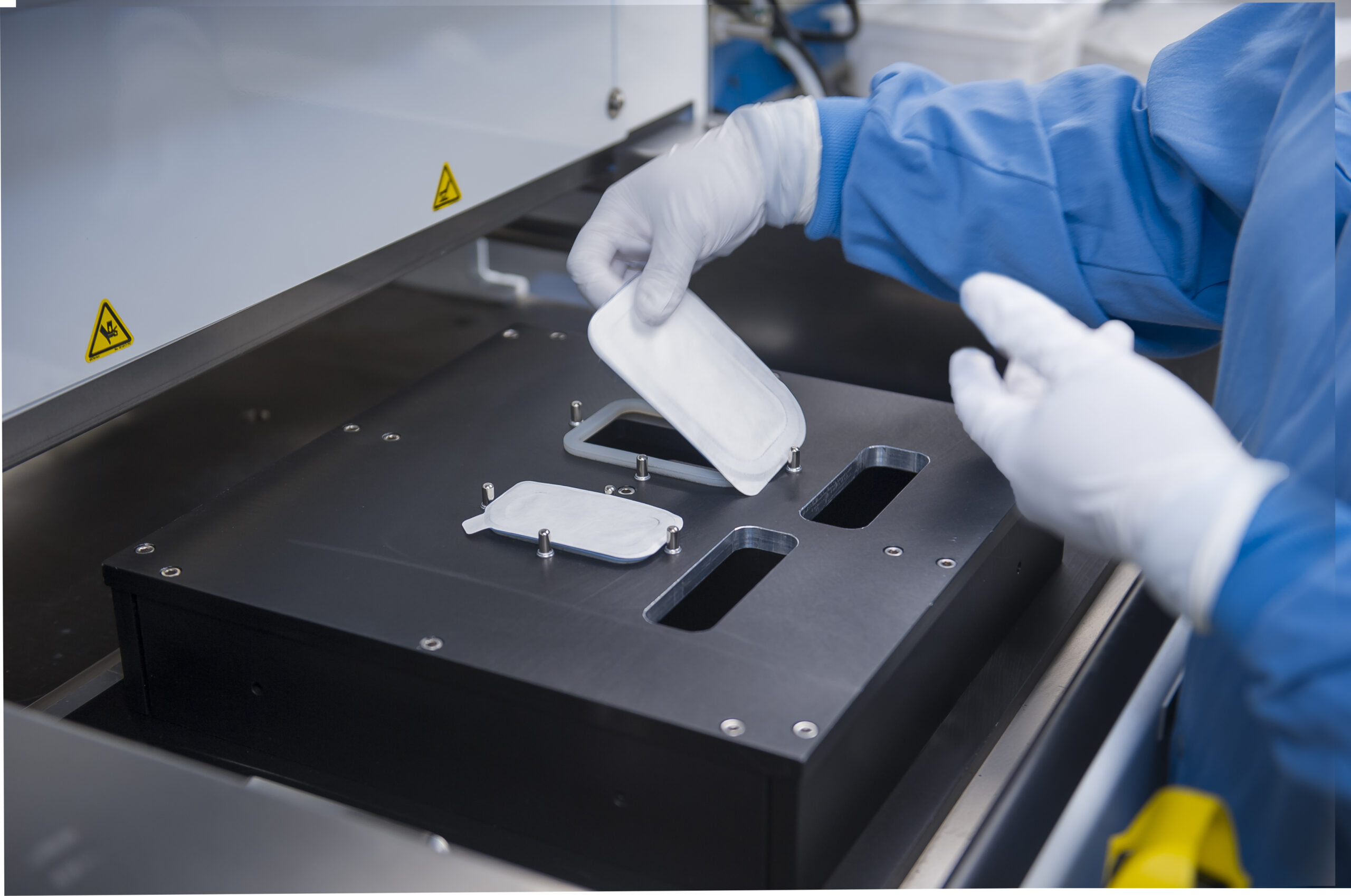

MEDICAL DEVICE CONTRACT ASSEMBLY

Pro-Tech Design & Manufacturing, Inc. provides full-service contract assembly services to the medical device industry.

We have over 10,000 square feet of certified Class 10,000/ISO 7-rated cleanroom space dedicated to medical device assembly, packaging, and kitting.

Your medical device can be cleaned, assembled, packaged, and labeled in the same facility, ensuring the highest level of quality

WHAT IS CONTRACT ASSEMBLY?

Medical device companies want to focus on what they do best, which is design life-saving medical devices.

However, when it comes to assembling and producing the final device, it is inefficient for them to invest the resources and time to build and maintain a cleanroom environment to assemble and package the product.

That’s where a medical device contract manufacturing company like Pro-Tech Design comes in. We operate cleanrooms with existing production lines available to assemble even the most complex products.

Additionally, with medical device contract assembly, you only pay for the production time devoted to assembling your device. Conversely, if you choose to assemble your device in-house, you absorb all the downtime of that assembly line which may only be operating for a fraction of a day or week.

Features

CLASS 10,000/ISO 7-RATED CLEANROOMS

Pro-Tech Design has invested in dedicated cleanroom space to ensure that your medical device is assembled in a protective environment to limit exposure to potential pathogens and to promote the safety and efficacy of your product.

Our cleanrooms feature HEPA fan filters, gowning rooms with air locks, temperature controls, sticky mats at entrance/exit, and gowning requirements. Production lines are cleaned regularly and strict protocols are in place to ensure your device remains safe throughout the production and assembly process. All our cleanrooms are tested monthly and certified annually to ensure compliance with regulatory standards.

PRODUCTION FLEXIBILITY

For most medical device companies, it is inefficient to set up an entire production line for a single product – particularly for a new, unproven one. At Pro-Tech Design, we have flexible production lines already set up to handle even the most intricate and complex assemblies. With state-of-the-art equipment, we can handle large volume production or custom manual assembly.

ASSEMBLY EFFICIENCY

Our experienced engineers are skilled at developing the most efficient assembly process to ensure that your medical device is assembled as quickly as possible to drive down costs without sacrificing quality.

Each product is assigned a manufacturing engineer to oversee it from concept to finished product. They are adept at using production time studies to develop the best practices to assemble your device.

Additionally, because of the range of medical devices we work with, we can bring in successful assembly practices from one line or product and apply it to yours without missing a beat.

Medical Device Assembly Capabilities & Services

Contract Assembly services to meet the needs of medical device customers large and small.

- Class 10,000/ISO 7-rated Cleanrooms

- Flexible Assembly Solutions

- Hand-Assembly & Automated Production

- Form-Fill-Seal

- Kitting

- Drug + Device Combination Capability

- State-of-the-art Equipment

- Production Time Studies

- Experienced Manufacturing Engineers

- Multi-component Assembly

Frequently Asked Questions

What services does PRO-TECH Design & Manufacturing offer?

PRO-TECH provides a wide range of medical device manufacturing and contract assembly services, including medical device packaging development and design, automated and hand assembly, and process optimization. Our contract assembly services ensure that all aspects of the product’s journey, from design to production, are handled with precision and efficiency.

How does PRO-TECH ensure quality in medical device manufacturing?

At PRO-TECH, quality is our top priority. We operate ISO 13485-certified facilities with clean room manufacturing spaces to maintain the highest industry standards. We also provide quality control throughout the device assembly process to ensure that your product meets all regulatory requirements.

What are the advantages of contract assembly services?

Contract assembly allows you to focus on the medical device design while we manage the production. By working with PRO-TECH, you only pay for production time, eliminating the costs associated with maintaining idle equipment. Our assembly facilities, state-of-the-art equipment, and experienced production staff ensure that your product reaches the market quickly and efficiently.

How does PRO-TECH support high-volume production?

Our assembly operations are designed to accommodate both small and high-volume production runs. With automated systems and hand-assembly capabilities, we provide flexibility to meet diverse client needs, from diagnostic devices to protective equipment. We also have three redundant manufacturing facilities that provide scalability and enhanced capacity.

What types of products can PRO-TECH assemble?

We specialize in medical device assembly. We work with a wide variety of customers in the medical device industry and can provide sterile or non-sterile assembly services for a broad range of applications Our comprehensive portfolio of medical device customers covers everything from cardiovascular to orthopedic to neurostimulation segments among others.

How does PRO-TECH manage the supply chain?

PRO-TECH offers supply chain management solutions, ensuring that every aspect of the manufacturing process is streamlined from start to finish. Our engineering expertise allows us to optimize the process time while maintaining cost-effective production strategies. We work with our clients to ensure seamless product-to-market delivery and full warehouse and logistics capabilities.

How do we get started?

Complete the contact us form and we will contact you to discuss the details of your project.

Our engineers will review the device and its components, confirm your requirements, and identify any production needs to outline an assembly protocol.

A detailed quotation will follow that includes production costs and any validation recommendations.