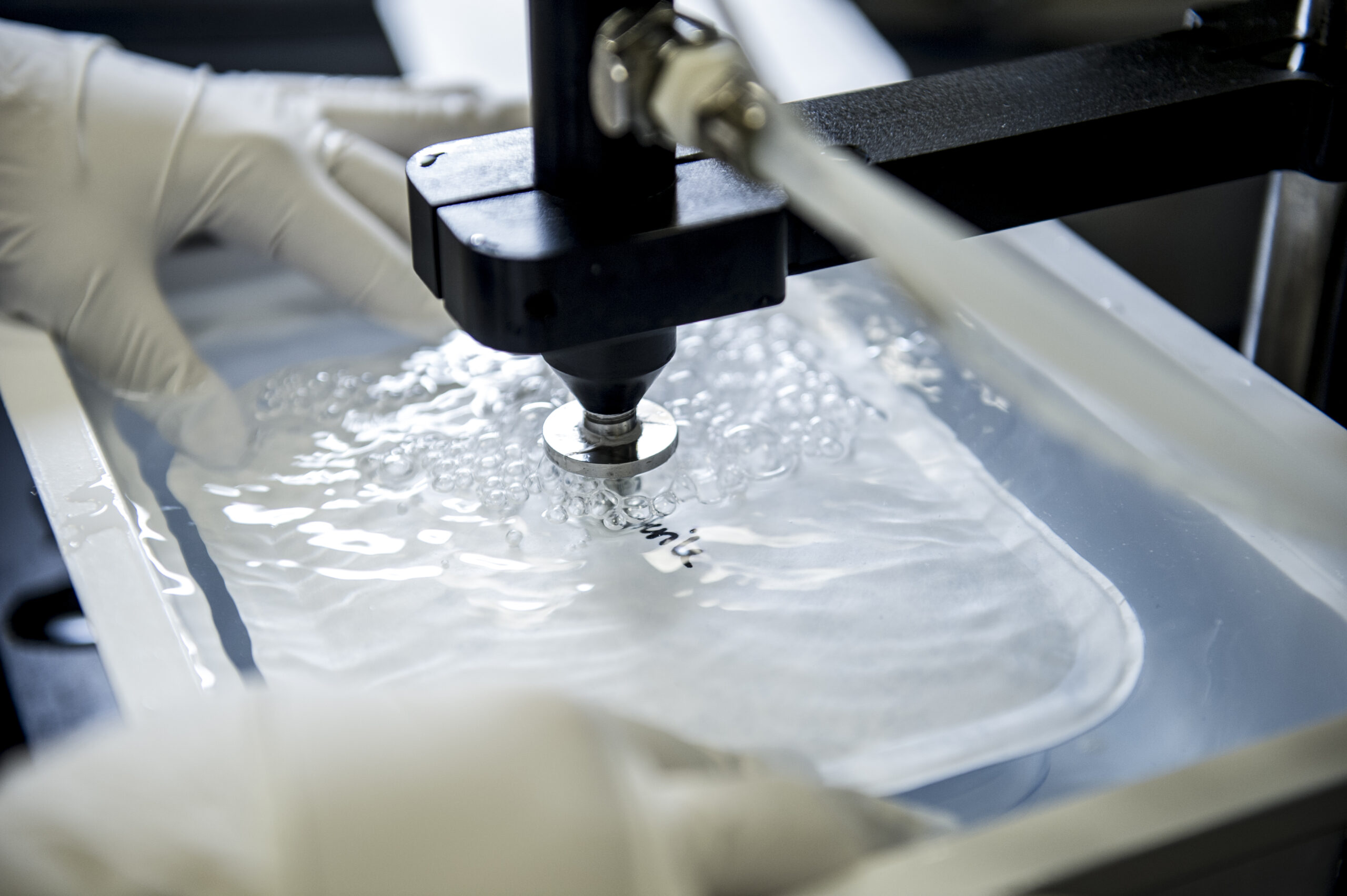

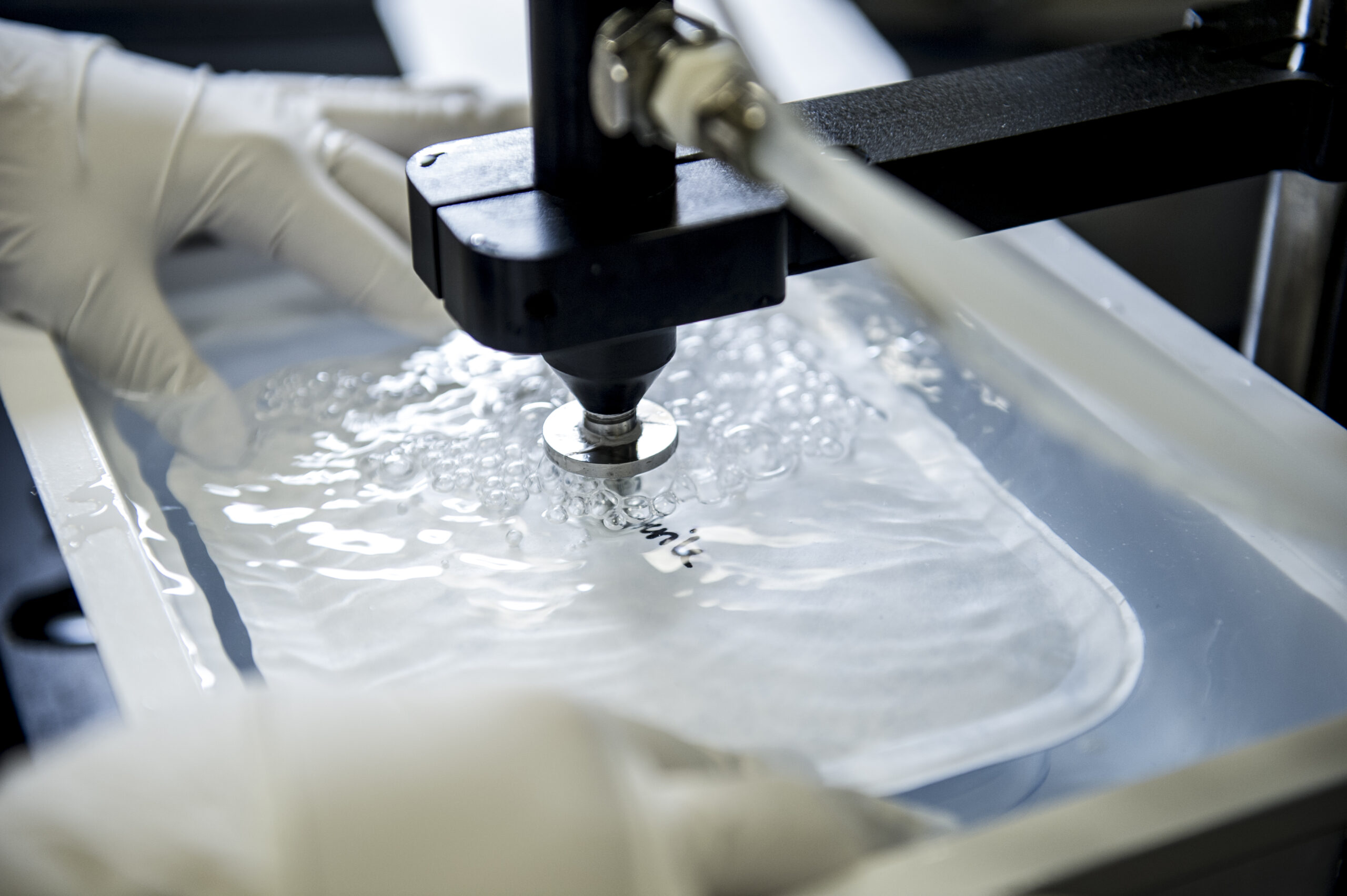

Bubble Leak Testing Service

Trusted bubble leak testing solutions to ensure your medical devices are safe, secure, and market-ready.

WHAT IS BUBBLE LEAK TESTING?

Bubble leak testing is a test method that determines the integrity of packages via gross leak detection. This test is crucial for ensuring that medical devices remain sterile and safe from contamination.

At PRO-TECH Design, we utilize this method to help manufacturers verify that their packaging can effectively protect their products throughout their lifecycle. We employ highly sensitive detection techniques to identify even the smallest leaks that might compromise the sterility of your medical products. Our rigorous approach ensures that every package is tested to meet strict quality and safety standards.

Explore Our Full Range of Services

In addition to bubble leak testing, we offer a full range of services to support the medical device industry, including:

- Complete Medical Device Assembly and Packaging: From start to finish, our cleanrooms and expert staff handle all aspects of device packaging and assembly.

- Sterilization and Validation Services: We provide full sterilization solutions, including validation of sterilization processes according to industry best practices.

- Custom-Designed Sewn Products: Protect your devices with custom solutions, from protective wearables to transport cases designed for durability and style.

- Advanced Laboratory Services: Our on-site ISO 17025 accredited lab supports all your testing and validation needs.

Why Choose PRO-TECH Design for Bubble Leak Testing?

At PRO-TECH Design, we not only provide testing services but also ensure that these services are tailored to meet the specific challenges of the medical device industry. Here’s why we stand out as a leader in bubble leak testing:

- FDA & ISO Compliance: Our testing procedures are rigorously designed to meet all regulatory requirements, ensuring that your products comply with industry standards.

- Custom Testing: We perform customized testing based on your specific needs and the unique requirements of your medical devices ensuring to meet the requirements of applicable ISO and ASTM standards.

- Expert Team: Our technicians are highly trained and experienced in conducting bubble leak tests, offering insights and solutions to any potential packaging issues.

Our Bubble Leak Testing Process

Phase 1 – Onboarding:

- Initial Inquiry: We assess your packaging needs and leak testing requirements.

- Requirements: Review specific device details, compliance standards, and timelines.

- Quote: Provide a customized quote outlining testing methods and standards.

Phase 2 – Testing:

- Preparation: Set up packaging samples for testing.

- Testing: Conduct bubble leak tests to detect any packaging integrity issues.

- Results: Provide detailed reports on test results and recommendations.

Phase 3 – Packaging Ready:

- Final Testing: Ensure packaging meets all FDA, ISO, and ASTM standards.

- Ongoing Support: Continuously review and improve testing processes as needed.

Contact us

Call Us

Tel: 562-207-1680

Fax: 562-207-1699

Email Us

info@protechdesign.com

Our Locations

CALIFORNIA

14561 Marquardt Ave.

Santa Fe Springs, CA 90670

TEXAS

4041 Express Street

Arlington, TX 76001

MINNESOTA

292 E. Lafayette Frontage Road

St. Paul, MN 55107