Packaging for medical devices is critical in maintaining the sterility and integrity of medical products, ensuring that they reach the end-user in a safe and usable condition. To ensure the packaging is reliable, robust, and meets regulatory requirements, medical device manufacturers need to validate their packaging systems.

In this article, we’ll take a closer look at the steps involved in medical device packaging validation. We will use Company A as an example, an existing customer of Pro-Tech Design, a medical device packaging design and manufacturing company. The customer had a new product that required a custom packaging configuration, and the following steps were taken to validate the packaging system.

Step 1: Determine the Best Packaging Configuration

Determining the best packaging configuration for a medical device product is a crucial step in the packaging validation process. The packaging configuration must protect the device from any potential hazards during transportation and storage while complying with regulatory requirements to ensure that the product can be safely used by end-users.

Company A wanted to use a dual sterile barrier system to package their product. Pro-Tech Design worked closely with Company A to evaluate different packaging options regarding pouch material options based on durability and sterilization requirements, pouch dimensions for their product, and shelf box options.

Step 2: Perform Applicable Packaging Studies

The next step is to perform applicable packaging studies on the chosen packaging configuration. These studies provide data on the packaging system’s performance under various conditions and help determine if the packaging system is suitable for its intended use. The customer decided they wanted Pro-Tech Design to perform all applicable packaging studies, which included:

- Baseline Study: This study is used to establish the sealing parameters (MIN/NOM/MAX) of the packaging system. It determines the optimal sealing temperature, pressure, and speed to achieve a consistent and reliable seal.

- Accelerated Aging Study: Aging study provides preliminary data to show product stability under accelerated aging conditions. It exposes the packaged product to high temperatures and humidity to simulate the effects of long-term storage.

- Real-Time Aging Study: This study provides real-time product stability data under normal storage conditions. It monitors the product’s stability over a period of time to determine if the packaging system maintains its integrity and the product’s efficacy.

- Distribution Study: The distribution study ensures the packaging will withstand typical transport conditions by simulating the effects of actual transportation on the packaged product, such as vibration, shock, and compression.

For each of these studies, the customer received a packaging validation protocol specific to their packaging configuration. Pro-Tech Design worked with Company A to generate a protocol that met ISO and ASTM requirements as well as customer requirements.

Step 3: Protocol Review and Approval

The protocol is a detailed document that outlines the study’s objectives, procedures, acceptance criteria, and data analysis plan for each packaging study. During the protocol review process, Company A had the opportunity to provide feedback on the study design and objectives. If any changes were made, the revised protocol was reviewed to ensure that all parties involved agreed to the revised protocol contents. Once the protocol drafts were finalized, they were reviewed and approved by Pro-Tech Design and the customer.

Upon protocol approval process, Pro-Tech Design began the process to start the packaging validation builds.

Step 4: Manufacturing Outline (MO)

Once the protocol was approved, the Engineering team generated a Manufacturing Outline (MO). The MO is reviewed and approved by the customer before manufacturing begins.

The MO describes all instructions including label print, manufacturing material, location, product assembly, sealing process, pack-out, and preparation for sterilization. Quality Assurance and Quality Control personnel are also involved to ensure the packaging system is manufactured correctly and meets regulatory requirements.

In the case of Company A, Pro-Tech Design’s Engineering team generated an MO that specified all instructions for their specific product and packaging. The MO was reviewed and approved by the customer before manufacturing began to ensure the customer was in agreement with the packaging process.

Step 5: Establish Sealing Parameters

If sealing parameters are not established for the packaging of choice, the first step is to determine the sealing parameters. The Engineering team determines MIN, NOM, and MAX settings through a Design of Experiments (DOE). Packages are sealed and tested to ensure the settings are acceptable via passing package test results. These parameters typically include sealing temperature, pressure, and speed necessary to achieve a consistent and reliable seal. Once established, the Cleanroom operators use these parameters to assemble the packaging system according to the MO’s instructions.

In the case of Company A, the Engineering team determined the optimal sealing parameters and worked with the Cleanroom operators to seal a predetermined quantity of pouches for both OQ and PQ builds. The Cleanroom operators followed the MO’s instructions to assemble the product and seal the pouches using the established sealing parameters. The established settings were utilized to seal the required quantity of pouches for all validation builds.

Step 6: Sterilization

The sealed packaging system was then sent for sterilization. The sterilization process ensures that the packaged product is free from microbial contamination and safe for patients to use.

There are several sterilization methods available, including ethylene oxide (EO), radiation, and steam. The method applied depends on the specific product and packaging system being used.

In the case of Company A, the Engineering team worked with the customer to determine the best sterilization method for the dual sterile barrier system using uncoated Tyvek. After considering the product’s specific requirements and the packaging system’s characteristics, the team decided to use EO sterilization.

Once the packaging system was sealed, it was sent to the sterilization facility for processing. The sterilization process was closely monitored to ensure that the packaging system was sterilized correctly and met regulatory requirements. After sterilization, the packaged product was tested to ensure that it was free from microbial contamination and met all product requirements.

Step 7: Package Testing

Once sterilization is complete, the packaged medical device goes through various package validation testing to evaluate the system’s performance against the acceptance criteria defined in the protocol.

The package testing includes various tests:

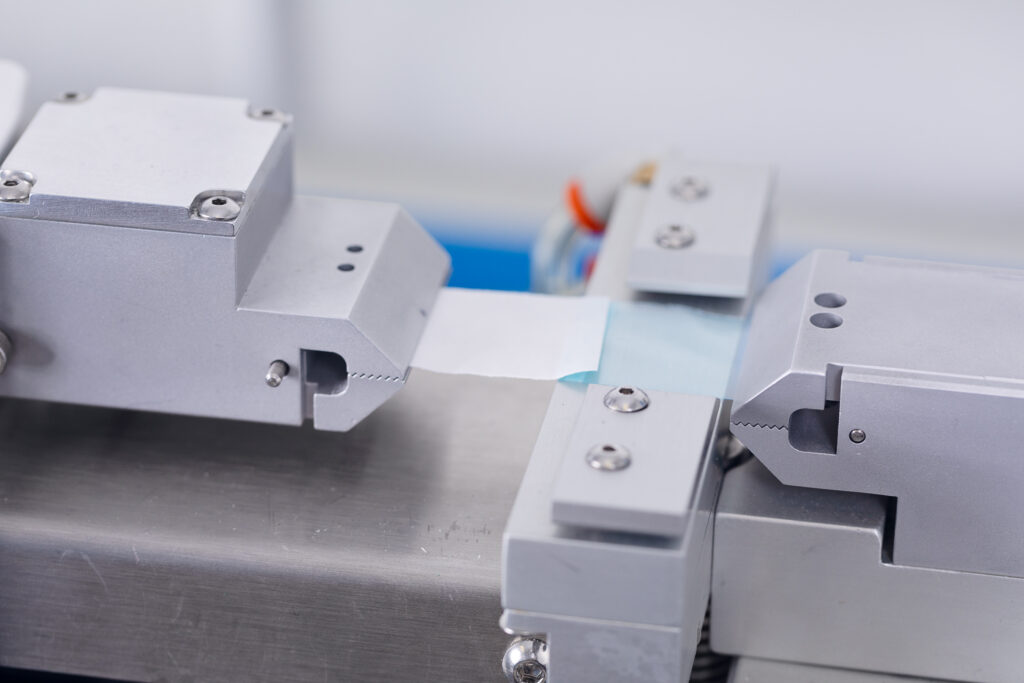

- Seal strength testing measures the force required to break the seal and ensures that the packaging system can withstand transportation and storage conditions.

- Integrity testing evaluates the packaging system’s ability to maintain a sterile barrier and prevent microbial contamination.

- Microbial barrier testing determines the effectiveness of the packaging system in preventing microbial penetration.

- Visual inspection ensures that the packaging system’s appearance is acceptable and that there are no defects or damages.

The test results are compared against the acceptance criteria defined in the protocol, and any deviations or non-conformities are addressed. If the packaging system meets the acceptance criteria, it is considered validated and ready for use.

In the case of Company A, Pro-Tech Design performed package testing on baseline samples, as well as aging and distribution study samples. It included seal strength, integrity, microbial barrier, and visual inspection tests.

Step 8: Final Report

After all testing was complete, a final report was written to summarize the study results and routed for approval. The final report includes a description of the packaging system, study objectives, procedures, results, and conclusions. It also includes any corrective actions taken during the study and the rationale for the acceptance criteria.

The final report is then reviewed and approved by the customer and Pro-Tech Design before it is considered complete. The customer may also use this report as part of their regulatory submission to demonstrate that the packaging system meets all applicable regulatory requirements.

In the case of Company A, Pro-Tech Design prepared a final report that summarized the entire packaging validation process for the dual sterile barrier system using uncoated Tyvek. The report included all of the packaging study results, any corrective actions taken, and the rationale for the acceptance criteria used.

Conclusion

Through the example of Company A and Pro-Tech Design, we have seen the steps involved in this process, from determining the best packaging configuration to final report generation. Each step was critical in ensuring that the packaging system was reliable, robust, and met regulatory requirements.

The successful completion of the validation process allowed Company A to bring their product to market with confidence, knowing that their packaging system was validated and met all applicable requirements.

If you are a medical device manufacturer, it is important to ensure the safety of your packaging system, and the best way to do so is by partnering with experienced and knowledgeable packaging design and manufacturing companies, such as Pro-Tech Design, to help you validate your packaging systems and achieve regulatory compliance.

If you need help validating your medical device packaging system, feel free to reach out to learn how they can assist you in the process.

By Reena Zachariah, Validation Engineer at Pro-Tech Design & Manufacturing, Inc.

By Reena Zachariah, Validation Engineer at Pro-Tech Design & Manufacturing, Inc.

Reena Zachariah is an experienced Validation Engineer. She has a Chemical Engineering degree from Drexel University in Philadelphia, PA. She has almost 20 years of experience in validations which ranges from various medical device equipment to processes to ensure process capability is met and maintained. Reena manages the packaging validation projects at PRO-TECH Design and our customers rely on her knowledge and expertise to ensure a smooth transition from the validation stage to commercialization.