Do you know that ASTM standards play a critical role in ensuring compliance for medical device contract packaging?

ASTM International, a standards development organization with a global reach, has set the bar for quality, safety, and performance in sterile packaging. To achieve regulatory compliance, medical device companies and their contract manufacturing partners must adhere to these industry standards.

With this article, we hope to shed light on the critical significance of adhering to ASTM standards. From defining the essentials of sterile packaging to outlining the key standards and the consequences of non-compliance, we’ll provide a comprehensive understanding of the role ASTM plays in ensuring the integrity and safety of medical devices in contract packaging.

ASTM and its Role in Setting Standards

ASTM International, founded in 1898 and formerly known as the American Society for Testing and Materials, is a globally recognized standards development organization. Its primary mission is to establish and publish voluntary consensus standards that cover a wide spectrum of industries, including medical devices. These evolving standards have historically addressed the challenges of ensuring the quality, safety, and performance of products and services worldwide, adapting to emerging industry needs.

Importance of ASTM in Sterile Packaging

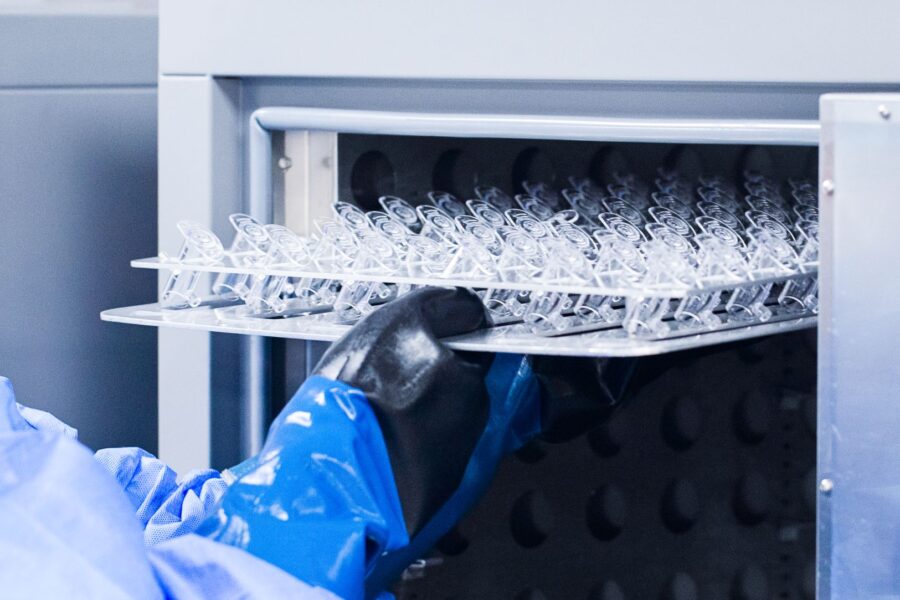

ASTM plays a pivotal role in defining standards for sterile packaging of medical devices, which includes specifications for manufacturing, packaging, and sterilization processes. These standards (more than 12,000), are continually updated to reflect current industry best practices, and offer precise instructions on materials, sterilization methods, and packaging techniques. They foster consistency across the industry, ensuring a common understanding and minimizing risks.

Sterile Packaging in Healthcare

- Preserving Sterility: The primary role of sterile packaging is to maintain the sterility of medical devices and pharmaceuticals. According to the U.S. Centers for Disease Control and Prevention, approximately 1.7 million patients in hospitals acquire healthcare-associated infections (HAIs) each year while receiving treatment for other conditions. In this context, the importance of sterile packaging becomes particularly evident. It serves as a critical barrier against microbial contamination, ensuring the safety and efficacy of medical devices.

- Patient-Centric Protection: At its core, sterile packaging is a commitment to patient safety and well-being. It safeguards not only the efficacy of medical devices but also the lives of those who depend on them. Patients entrust their health to the sterile packaging that encases and protects these essential healthcare items.

- Medical Device Integrity: Beyond patient safety, sterile packaging plays a role in maintaining the integrity of medical devices. Whether it’s a precision surgical instrument or a complex implant, these devices must function flawlessly when called into action. Sterile packaging ensures that they do so by preventing damage or contamination that could compromise their performance.

- A Synonym for Trust: In the eyes of patients and healthcare providers alike, sterile packaging is, and should be, synonymous with trust. It signifies a commitment to the highest standards of safety and reliability. When medical device products are removed from their sterile packaging, they carry with them an implicit promise—a promise of uncompromised sterility and performance.

Significance of Complying with ASTM Standards

It is also important to understand why complying with ASTM standards is not just an option but an absolute necessity:

- Ensuring Product Safety: Compliance with ASTM standards is the linchpin for ensuring the safety of medical devices and healthcare products. These standards are crafted to mitigate risks, prevent contamination, and uphold the highest levels of sterility. By adhering to these standards, companies demonstrate their commitment to patient safety.

- Regulatory Compliance: The medical device industry is heavily regulated to guarantee the highest standards of quality and safety. Regulatory bodies, such as the U.S. Food and Drug Administration (FDA), often refer to ASTM standards when evaluating the safety and efficacy of medical devices and packaging. Compliance with these standards simplifies the regulatory approval process, ensuring that products meet the necessary requirements for market access.

- Industry Best Practices: ASTM standards represent industry best practices and collective wisdom garnered over years of research, development, and experience. Following these standards is akin to leveraging the collective knowledge of experts to produce healthcare products of unparalleled quality.

- Minimizing Risks: Non-compliance with ASTM standards can introduce unnecessary risks into the production process. These risks include contamination, compromised sterility, and decreased product efficacy. By adhering to established standards, companies minimize these risks, protecting both their reputation and the health of patients.

- International Recognition: ASTM standards are recognized and respected worldwide. When companies comply with these standards, they gain international recognition for their commitment to quality and safety. This recognition can open doors to global markets and collaborations.

- Customer Confidence: Patients and healthcare providers trust in the reliability and safety of healthcare products. Compliance with ASTM standards provides an added layer of assurance, instilling confidence in the products and the companies that produce them. It’s a way of saying, “We prioritize your well-being.”

Key ASTM Standards for Sterile Packaging

ASTM standards are not a one-size-fits-all solution; they are tailored to specific aspects of sterile packaging and medical devices. Here are some key ASTM standards for ensuring the integrity and safety of sterile packaging for medical devices:

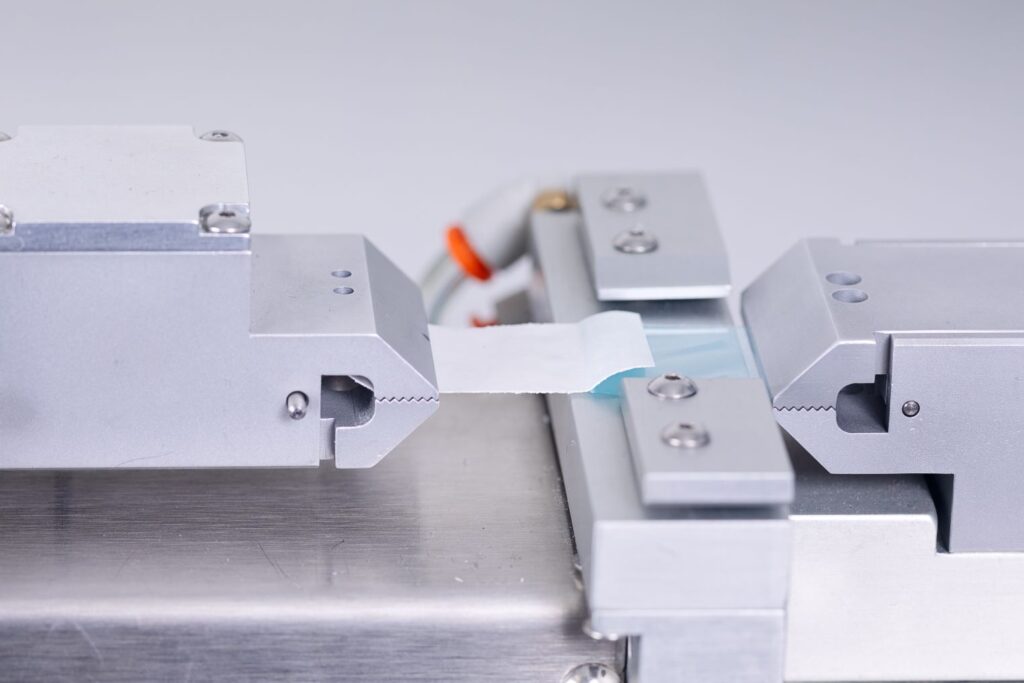

- ASTM F1929 – Test Method for Detecting Seal Leaks in Porous Medical Packaging by Dye Penetration: This standard provides a technique for identifying seal leaks in porous packaging materials commonly used in medical devices. It helps detect even minor imperfections in the seals that could allow contaminants to enter.

- ASTM F1980 – Accelerated Aging of Sterile Barrier Systems for Medical Devices: Aging is a critical consideration in sterile packaging, and this standard helps assess how packaging materials and systems will perform over time, especially under the stress of accelerated aging conditions. It ensures that the sterile barrier remains intact and effective throughout the product’s shelf life.

- ASTM F2096 – Detecting Gross Leaks in Packaging by Internal Pressurization (Bubble Test): ASTM F2096 focuses on detecting large leaks in sealed packaging, which could compromise the sterility of the contents. It helps identify significant defects that might not be apparent through visual inspection alone.

- ASTM F88 – Standard Test Method for Seal Strength of Flexible Barrier Materials: Evaluating the seal strength of flexible packaging materials is vital to guarantee that the sterile barrier remains intact throughout the product’s lifecycle. This standard provides a consistent method for assessing the strength of seals.

- ASTM F1886 – Standard Test Method for Determining Integrity of Seals for Medical Packaging by Visual Inspection: ASTM F1886 is typically a first measure of detecting seal integrity where the testing technician inspects the package to ensure the seal area is free of channels, wrinkles, ruptures, and any other defect that could impact the integrity of the seal. Additional tests may be performed to confirm defects.

Collectively, these ASTM standards provide a systematic and standardized approach to evaluating and maintaining the integrity of sterile packaging for medical devices. Each of them plays a specific role in ensuring the integrity of sterile packaging.

Consequences of Non-Compliance

Non-compliance with ASTM standards can have profound and far-reaching consequences not only for the companies involved but also for the health and safety of patients.

- Patient Safety: Since the patient’s safety is the primary concern in healthcare, the most important risk of non-compliance is jeopardizing safety by increasing the likelihood of contamination or compromised sterility of medical devices. Patients rely on these devices for their health and well-being, and any compromise in their integrity can lead to adverse health effects or even fatalities.

- Product Recalls: When medical devices packaged without adherence to ASTM standards are found to be non-compliant or potentially unsafe, it can result in costly and damaging product recalls. These recalls not only erode trust in the company but also lead to significant financial losses, legal liabilities, and damage to the company’s reputation.

- Regulatory Penalties: Regulatory bodies, such as the Food & Drug Administration, have stringent requirements for medical device packaging. Non-compliance with ASTM standards can lead to regulatory penalties, including fines, delays in market approval, or even the suspension of a company’s ability to manufacture or sell medical devices.

- Loss of Market Access: Many countries and regions require medical devices to meet specific packaging standards to gain market access. Non-compliance can result in the exclusion of products from lucrative markets, limiting a company’s growth and revenue potential.

- Increased Costs: Correcting packaging issues after non-compliance is discovered can be more expensive than ensuring compliance from the outset. Remediation efforts, such as redesigning packaging, retesting products, and addressing regulatory concerns, can be very costly.

Placing a high priority on adhering to these standards clearly goes beyond mere regulatory compliance; it represents a fundamental dedication to safety and the enduring prosperity of a company within the healthcare sector. This commitment not only safeguards the integrity of the products but also fortifies the company’s reputation, and, ultimately, reflects its dedication to the well-being of individuals worldwide, making a tangible difference in the realm of healthcare.

Tips for How to Comply with ASTM Requirements for Sterile Packaging

To navigate the complex landscape of ASTM requirements for sterile packaging, companies should:

- Establish a compliance team that includes experts in packaging, quality control, regulatory affairs, and other relevant areas

- Perform a gap analysis and update packaging processes based on the outcome

- Implement best practices for packaging design, materials selection, and sterilization processes

- Provide training programs to educate employees on the importance of compliance and the specific requirements they need to follow

- Conduct regular quality control checks and testing to verify compliance

- Collaborate with experts in the field to stay updated on industry trends and regulatory changes

- Maintain meticulous records of all packaging processes, tests, and compliance efforts

- Consider pursuing certification from recognized bodies that specialize in packaging compliance

- Stay informed about the latest ASTM standards relevant to their products

Achieving compliance with ASTM requirements is not merely a checklist of tasks to be completed. It’s an ongoing commitment to the highest standards of safety, quality, and patient well-being. Given that the medical device industry is a dynamic and evolving landscape, companies must remain adaptable and responsive to changes in regulations and technologies.

By fostering a culture of continuous improvement and vigilance, companies can not only meet the current ASTM standards but also anticipate and adapt to future requirements. This proactive approach ensures that their sterile packaging practices remain at the forefront of patient safety and regulatory compliance.

By following the recommended practices and embracing a culture of continuous improvement, companies can navigate the complex terrain of sterile packaging with confidence, knowing they are safeguarding the health and well-being of patients while securing their own success in the industry.

Summary

- ASTM International is a globally recognized standards development organization.

- ASTM standards are essential for compliance in medical device contract packaging.

- Compliance ensures the quality, safety, and performance of sterile packaging.

- Preserving sterility in medical devices is a primary function of sterile packaging.

- Key ASTM standards for sterile packaging include leak detection, seal integrity, and aging assessment.

- Complying with ASTM standards is a commitment to safety and reputation.

- Tips for compliance include establishing a dedicated team, gap analysis, best practices, training, quality control, collaboration, record-keeping, certification, and staying updated.

- Compliance requires ongoing commitment, adaptability, and a culture of continuous improvement.